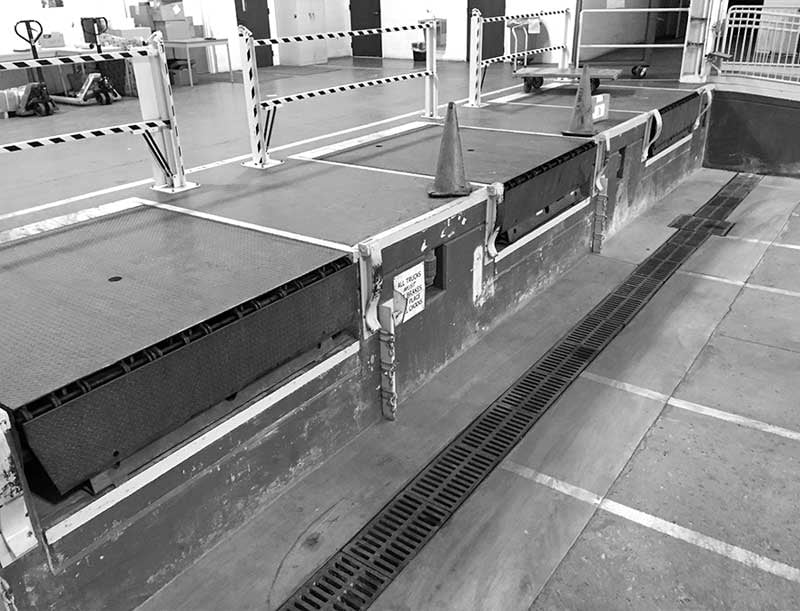

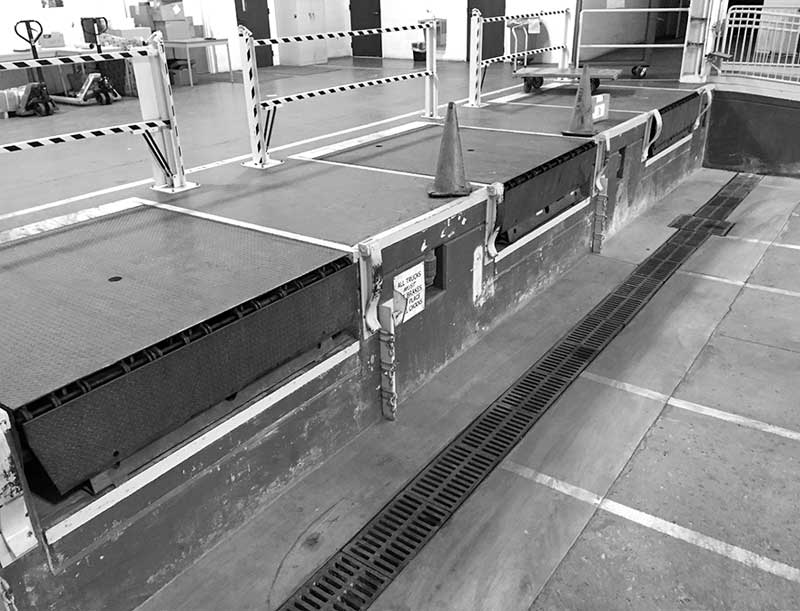

Warehouse Loading Dock & Door Equipment, Installation, Service, Maintenance, Repair, Accessories

Maximizing efficiency and safety with high-performance dock & door solutions tailored for industrial, commercial, and warehouse applications.

Dock & Door Solutions

We offer dock and door equipment, accessories, and services to keep your facility running safely and efficiently.

Levelers

Hydraulic levelers require minimal maintenance while manual dock levelers feature a hinged-lip design and pull-chain manual control.

Restraints/Locks

Loading dock trailer truck restraints (or locks) are devices that latch onto trailers to help keep them from separating from the dock during loading.

Wheel Chocks

Loading dock wheel chocks provide superior holding power on virtually any hard surface and come in rubber, urethane, aluminum, and laminate.

Stabilizing Jacks

Trailer stabilizing jacks are used to prevent up-ending of semi-trailers when they are not connected to a tractor during loading and unloading operations.

Doors, Seals & Shelters

Keep bad weather and pests outside. Dock doors, seals and shelters protect products and reduce energy costs. Choose from various colors and fabrics such as vinyl, PX420, and neoprene.

Scissor Lift Tables

Improve productivity and minimize injury with a 12,000 lb capacity scissor lift table. Workers can easily adjust the table to the ideal working height – from 24" to 72".

Edge Of Dock Levelers

Edge-of-dock levelers are lower-cost alternative to dock levelers for operations that receive trucks with little variance in trailer height.

Barriers & Rails

Loading dock barriers and guardrails help prevent tragic injuries. Rails are available in standard lengths of 4′, 5′, 6′, 7′, 8′, 9′, and 10′.

Commercial Doors

Keep the weather outside and maintain the temperature in your commercial building with insulated doors.

High-Speed Doors

High-performance doors provide fast and durable operation, making it perfect for busy areas and locations prone to impacts.

Maximum Seal Doors

Fast opening speeds, wide vision, and maximum protection seal help to increase productivity, maximize safety, and reduce energy loss.

Clean Room Doors

Our clean room doors feature sealed edges, which keep out dust, dirt, and debris ensuring interior remains clean and dry.

Safety Accessories

We carry the most practical items and customized solutions to enhance the safety of those working around high-speed doors and loading docks.

Dock & Door Installation

We help you increase efficiency and safety within your operation. We will visit your facility and provide custom solutions.

Dock & Door Repair Service

Keep your operation running efficiently with responsive expert dock and door repair from The Lilly Company.

Dock & Door Maintenance

Dock and door maintenance helps reduce the possibility of downtime and the lost revenue that results from it.

INCREASE SAFETY & EFFICIENCY

Loading docks can be dangerous places for employees and forklifts. Prevent injuries and be OSHA compliant. We can help.

Don't Let Small Issues Turn Into Expensive Problems

Schedule a FREE 50-Point Dock & Door Safety Inspection

For a limited time, we’re offering a no-sales-pressure FREE 50-point Dock and Door Safety Inspection to help you:

-

Avoid downtime and disruptions

-

Ensure everything runs like clockwork

-

Protect your business from lawsuits and liability risks

-

Keep your employees safe and reduce the risk of workplace injuries

Our Dock & Door Partners

We help you to improve safety and efficiency with these trusted brands:

LOADING DOCK EQUIPMENT

Whatever your dock needs are, we can help you find new or used loading dock equipment that will quickly pay for itself in improved productivity.

Not sure if which loading dock equipment is right for you? Ask us about our free on-site assessment.

From the Blog

Dock & door products, services, and accessories.

3 min read

How To Choose a Loading Dock Door

Oct 20, 2023 by John Wofford

3 min read

Dock Door Maintenance vs. Repair - Which One Costs Less?

Aug 18, 2023 by John Wofford

.jpg?width=600&height=374&name=Loading_Dock_Lifestyle_Photo_BW_7_600px%20(1).jpg)