Your forklift’s data plate (also known as a nameplate) provides essential information about the truck’s capabilities and limitations. Every forklift operator should understand how to read forklift data plates, especially the load capacity chart.

The forklift load capacity chart tells you how much weight the truck can handle. Without this information, an operator could overload the truck and experience a tip-over. Tip-over incidents are always expensive, sometimes tragic and easily prevented. Read on for a detailed explanation of how to read a forklift data plate and understand the load capacity chart.

The Forklift Data Plate: Explained

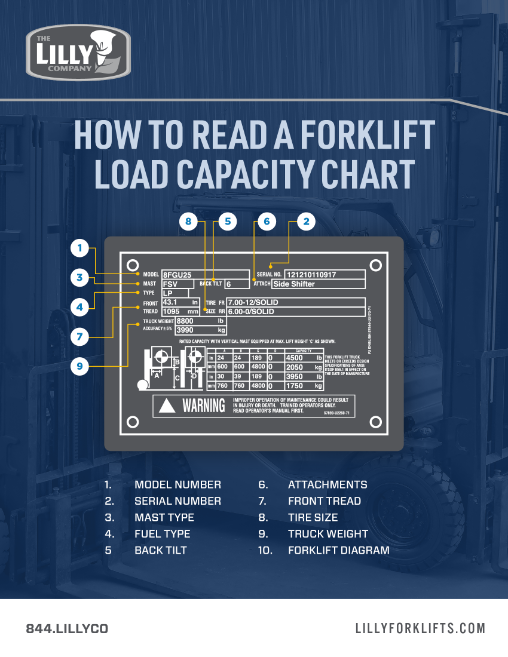

A forklift’s data plate or nameplate (the terms are used interchangeably) is typically found on or near the instrument panel. The information and layout varies by manufacturer, but most data plates include the:

- Forklift Model and Serial Numbers — Useful when shopping for forklift parts or when requesting forklift repair

- Attachments — Listed because they can affect the forklift’s capacity

- (Fuel) Type — Usually abbreviated: compressed natural gas (CNG), diesel (DS), electricity (E), gasoline (G) or liquid propane (LP)

- Truck Weight — The total weight of the forklift

The data plate may also include the forklift’s:

- Back Tilt — How many degrees the mast can tilt backwards (toward the operator) to help keep a load on the forks

- Front Tread — The overall width of the forklift

- Mast Type — 2-stage (V or FV), 3-stage (FV) or 4-stage (QFV)

- Tire Size — What size and type of tire to use: Solid (pneumatic tires), Smooth or Treaded (cushion tires)

How To Read a Forklift Load Capacity Chart

The most important piece of information on the data plate is the load capacity chart. A forklift’s capacity can change depending on the load center and how high the load will be lifted. For example, A forklift may have a maximum capacity of 4,500 lbs if the operator is simply driving around. But, if a load must be lifted to the mast’s maximum extension and put on a shelf, the capacity may drop to 3,950 lbs.

The load capacity chart, always located somewhere on the forklift’s nameplate, is where you can find the information above. Look for a chart next to a simple forklift diagram labeled with the letters A, B, and C.

The diagram shows what each letter refers to. “A” could be the maximum fork height or it could be the horizontal load center. Labels can differ by manufacturer, so always check the diagram to confirm.

What is a Load Center?

OSHA describes a load center as, “the distance from the face of the forks to the load’s center of gravity.” Put in real-world terms: if a forklift is carrying an evenly-distributed load on a 48” by 48” pallet, the load center is 24” (the center of the pallet).

How does this apply to the nameplate?

If the load capacity chart on your forklift’s nameplate looks like this:

A: 189 | B: 24 | Capacity: 3000

A: 189 | B: 30 | Capacity: 2400

…it means your forklift can carry up to 3,000 lbs provided the load center is 24”. If the forklift picks up a load that’s a foot longer, the load center moves to 30” and the forklift’s capacity drops to 2,400 lbs.

If that doesn’t intuitively make sense, imagine picking a box up off the floor:

- By wrapping your arms around the box and standing straight up

- Versus picking up the box while holding it as far away from your body as possible

The second option takes a lot more effort, right? The same goes for your forklift.

What About Electric Forklift Data Plates?

An electric forklift’s data plate will include the rated capacity information described above. It may also include information about the truck’s battery requirements and electrical system. These details can be helpful to ensure operators use the correct batteries and charging equipment.

Still Have Questions? We’re Happy to Help

Our experienced and friendly forklift experts can answer any questions you may have. The Lilly Company is an authorized forklift dealer for Toyota, Clark, Komatsu and Linde and we’re proud to serve customers throughout Alabama, Mississippi, Tennessee and eastern Arkansas.

Contact a forklift expert at The Lilly Company online or by phone 844-LILLYCO (1-844-545-5926) with any questions you have. Or, come say hello at one of our 13 locations across the Mid-South.

Arkansas – Jonesboro

Alabama – Birmingham, Dothan, Irondale, Madison, Mobile, and Montgomery

Mississippi – Tupelo, and Richland

Tennessee – Jackson, Memphis, Knoxville, and Kingsport

Further Reading:

Forklift Extensions: What You Need to Know

Understanding Forklift Deration

Custom Paint Jobs for Your Forklift or Other Equipment

Posts by Tag

- Forklift (61)

- Forklift Service (19)

- Electric Forklifts (16)

- Forklift Safety (14)

- Forklift Attachments (12)

- Toyota Forklifts (12)

- Warehouse Planning (10)

- Parts (9)

- Warehouse Automation (8)

- Clark Forklifts (7)

- Loading Docks (7)

- Material Handling Education (7)

- Pallet Racking (7)

- Customer Solutions (6)

- Forklift Batteries (6)

- Purchasing Options (6)

- Aerial Equipment (5)

- Forklift Rental (5)

- Heavy Equipment (5)

- Forklift Accessories (4)

- Forklift Fleet Management (4)

- Forklift Tires (4)

- Forklift Training (4)

- Products (4)

- Yard Spotter Trucks (4)

- Linde (3)

- Specialty Forklifts (3)

- Used Equipment (3)

- Utility Vehicles (3)

- IC Forklifts (2)

- Manitou (2)

- Pallet Jacks (2)

- Warehouse Doors (2)

- COMBiLift (1)

- Custom Shop (1)

- Forklift Brakes (1)

- Forklift Warranty (1)

- Gehl (1)

- Komatsu (1)

- Product Review (1)

- Recruitment (1)